Scribe Rule

Scribe rule is a way of marking out the joints, between timbers that may have any of a number of irregularities, accurately enough to ensure a good, structurally sound fit when assembled.

The design of the frame is done in such a way that the various two dimensional sections of the structure (cross frames, wall frames, roof frames etc.) can be dealt with as separate units by the carpenters in the workshop, each one being laid out and cut in a horizontal position to allow easy handling.

The basic elements of the process are these:

The major timbers are laid out on trestles, usually over a drawing on the framing floor, representing a section (a cross section or a wall elevation for example) of the building, which allows them to be positioned exactly in relation to each other. This is done by way of a plumb bob with a hole in the middle which allows the framer to see the chalk lines and other marks on the floor.

are laid out on trestles, usually over a drawing on the framing floor, representing a section (a cross section or a wall elevation for example) of the building, which allows them to be positioned exactly in relation to each other. This is done by way of a plumb bob with a hole in the middle which allows the framer to see the chalk lines and other marks on the floor.

The timbers in this 'lay up' must also be horizontal, but the faces of them are probably bent or twisted and difficult to level accurately, so usually ink or chalk lines are applied and used as references. These are later removed by the sand blasting done on site. Instead of these lines I often use a laser level, working to datums, to achieve the same end, which leaves the timbers cleaner and gives more choices when considering the frame finishing options.

and gives more choices when considering the frame finishing options.

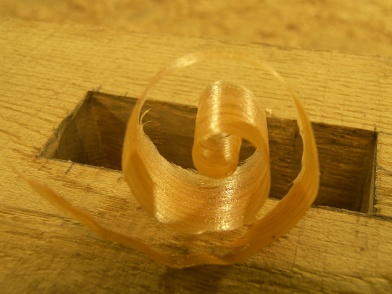

The various elements are laid one over the other in a kind of stack, which allows for the next stage in the process to take place which is where the actual “scribing” of the joints happens. The scribing is usually done with a plumb bob, whose string, thanks to gravity, is always vertical, which allows the transfer of information from the lower piece to the upper piece or vice-versa.

A couple of examples of excellent drawings of the traditional French version of scribe rule, called le piquage (the mother of all modern versions really), drawn by Marc Guilhemjouan can be seen here and here, and a very nice overview of the more typical English version that I use can be found in Rupert Newman's book Oak-Framed Buildings.  Once everything in the 'lay up' is marked out the joints can be cut, and the frame reassembled to allow checking of the fit and marking of the tenons for the draw boring (described back on the "About oak frames" page).

Once everything in the 'lay up' is marked out the joints can be cut, and the frame reassembled to allow checking of the fit and marking of the tenons for the draw boring (described back on the "About oak frames" page).

Finally the parts of the frame are tagged with the traditional chiselled numbering system so that there is no chance of confusion when assembling the frame on site in the vertical position.

Apart from the ease with which one can deal with bent and otherwise irregular timbers by using thi s method, there are other advantages. For example it is very easy to deal with unusual geometries, allowing the prefabrication of complex and irregular roofs and poligonal structures with relative ease, even without recourse to Computer Assisted Design software.

s method, there are other advantages. For example it is very easy to deal with unusual geometries, allowing the prefabrication of complex and irregular roofs and poligonal structures with relative ease, even without recourse to Computer Assisted Design software.

J. Rose Carpentry

J. Rose Carpentry